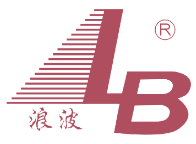

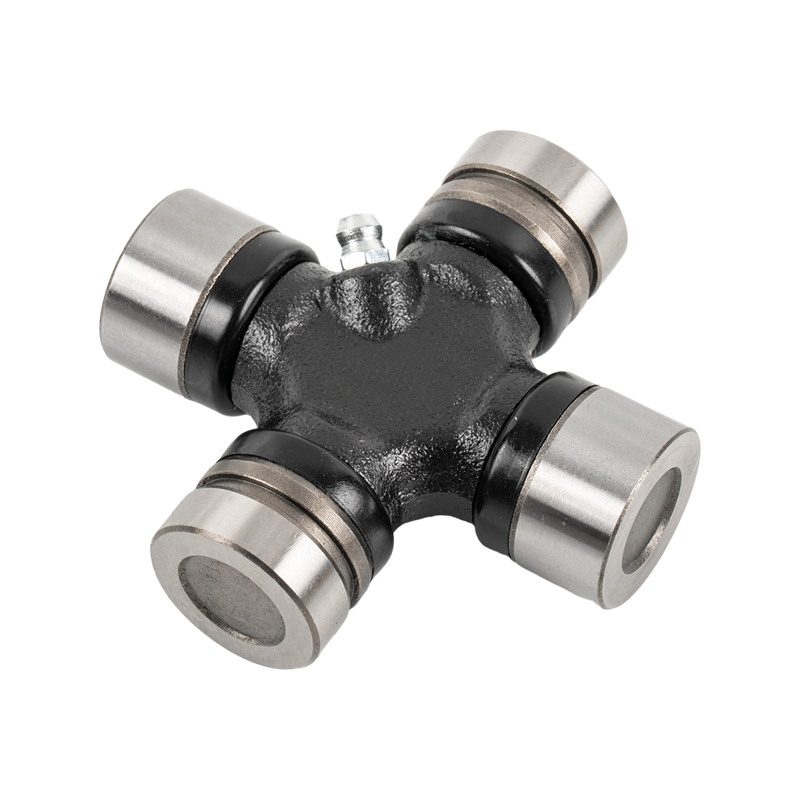

Zhejiang Weigang Technology Co., Ltd. (formerly Hangzhou Xiaoshan Weigang Auto Parts Co., Ltd.) was founded in 1997, located in Qianjiang River, Ningwei Town covers an area of 15,000 square meters, producing "wave" (LB) universal joints, bearings and other auto parts, with the "market-oriented, customer-driven, technology-based" business policy, the implementation of ISO9001 national quality system standards, product quality excelență.

- A urmat standardul de calitate al sistemului ISO9001: 2008 în 2014.

--- Actualizat în 2018 pentru a implementa standardul sistemului de calitate IATF16949: 2016

--- și-a schimbat numele în

Zhejiang Weigang Technology Co., Ltd. În septembrie 2018, s-a mutat pe numărul 77, Qihang Road, Sanjie Town, Shengzhou City, Shaoxing City, compania acoperă o suprafață de 43.000 de metri pătrați, cu o producție anuală de 4,50-5,5 milioane de articulații.

6 Linia de producție a echipamentelor Forge, strungurile CNC sunt de peste 50 de seturi , Peste 60 de seturi de mașini de măcinare, mai multe utilaje și echipamente automate, 6 noi linii de forjare, 2 linii de asamblare etc., în urma filozofiei de afaceri a „investițiilor înalte, echipamente de înaltă preț, talente la nivel înalt, produse de înaltă calitate” și aderarea la extinderea pieței interne și externe.